I love data and I love the accumulation and processing of data in the pursuit of insights and maybe even truth. I love systems that categorise data and reveal structure that is not always obvious. With a small amount of data, or lots of data but collected over a very short period of time it is hard to decipher what is going on. However, as time spans lengthen and more data is available, it becomes possible to see patterns.

A subject that I have always been interested in is “types of people” or “working styles” for example the Myers-Briggs system, created by Katherine Cook Briggs and her daughter Isabel Briggs Myers, and by the DISC system first put forward by William Moulton Marston in the first half for the 20th Century. Both systems have undergone progressive refinements ever since. These studies are, to this day, described as “Pseudo Science” by Wikipedia and yet they are used by small and large companies to identify qualities of job applicants and existing staff to establish how best to create functioning teams to work on projects.

Over the last 35 years I have worked on 10 years worth of Architectural projects and 25 years of database projects. Architectural projects can last for years and some of the database systems I have created have run for as long as 25 years giving ample time top observe the characters of the people involved. During that time I have worked closely with my clients to produce the desired project outcomes and as a result of this I have accumulated some insights into the working styles of my client project managers and their bosses.

Whilst the Myers-Briggs and DISC systems are useful I have not asked my clients to run tests to find out what their type is based on these systems, though this would be a great idea!

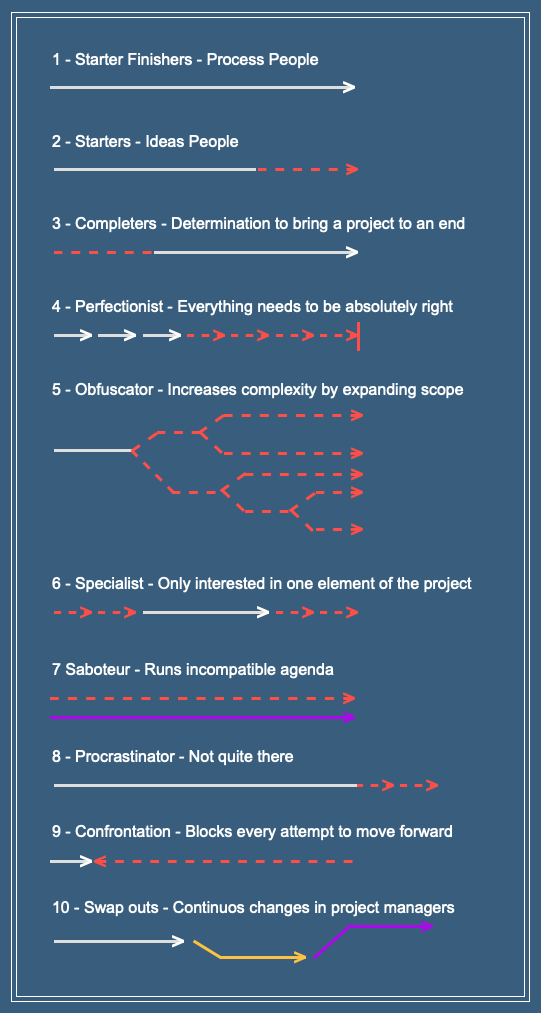

Instead, in reviewing my engagement with my clients, I have extracted some types of my own. These types, with a lot more study, could most certainly be assigned a category from the above systems but I hope mine offer some more immediate and accessible insights.

Note that, of course, none of the types is either “right” or “wrong”, but they do affect the outcome of a project and knowing what types are involved in the execution of a project helps increase the chances of a project being completed successfully. Not knowing which types are involved and not taking remedial action can lead to unnecessary costs, delays and even the abandonment of the project.

So over a series of 10 posts, and one concluding post, are my types. Each type includes a description of what I have found the positive and negative impacts to be, what the intentions of each type are and what remedial action I suggest be taken to increase the chances of success of any type of project. Remember that the types apply to all the members of a team and all are influencing the outcome, this includes you/me! The list of types is of course incomplete but 10 will suffice for now!

This is written from the viewpoint of a consultant but is still valid for projects run in house.

My intention in offering up this series of 10 “types” is it to help project managers avoid some of the losses incurred by acknowledging these traits and exploiting their virtues and avoiding their vices.

I was reviewing the next step of a system with a client today and he was asking how he could delegate more responsibility to his site managers.

I was reviewing the next step of a system with a client today and he was asking how he could delegate more responsibility to his site managers.